From Foundries to Fields: Exploring the Role of Valve Casting in Agriculture

Last updated on June 24th, 2024 at 11:12 am

Table of contents

When you think of agriculture, images of vast fields, hardworking farmers, and bustling markets likely come to mind. But what about valve casting? You may not realize it, but this age-old technique has played a crucial role in revolutionizing modern agriculture. From ensuring efficient irrigation systems to enhancing crop protection measures, Valve Casting in Agriculture has silently been working behind the scenes to fuel agricultural productivity. Join us on this journey as we delve into the fascinating world of valve casting and uncover its significant impact on the field!

What is valve casting?

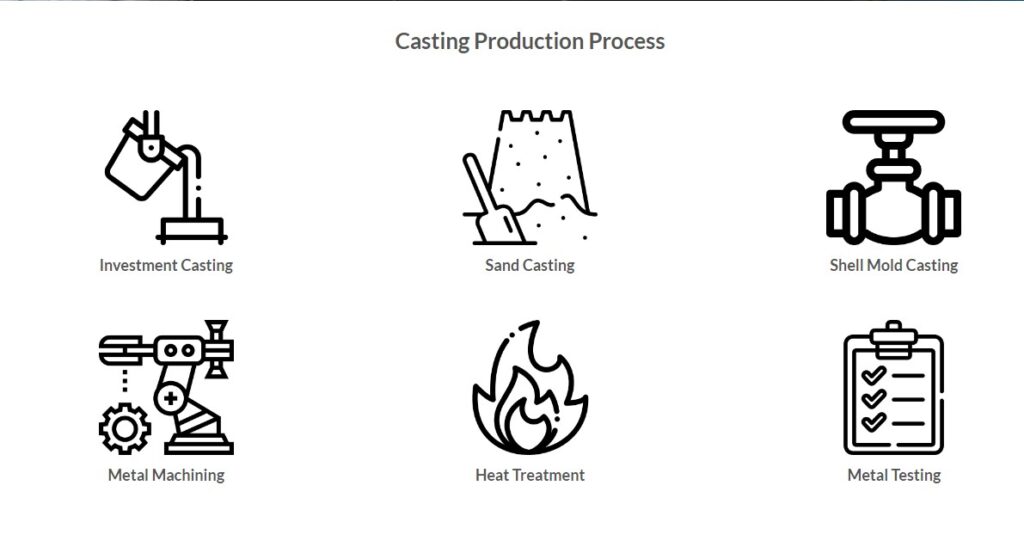

Valve casting is a manufacturing process that involves the creation of intricate metal valves through the use of molds and molten metal. It is a technique that has been practiced for centuries, allowing for the production of high-quality valves with precise specifications.

At its core, valve casting begins with the design and creation of a mold, which is typically made from materials such as sand or ceramic. The mold acts as a negative space in which molten metal can be poured to create the desired valve shape. Once the metal has solidified within the mold, it is then removed, leaving behind a fully formed valve ready for use.

This technique offers numerous advantages over other methods of valve production. It allows for greater design flexibility and complexity, enabling manufacturers to produce valves tailored to specific agricultural applications. Additionally, valve casting ensures consistent quality and accuracy in each produced part, leading to improved performance and reliability in agricultural machinery.

Moreover, valve casting enables cost-effectiveness by reducing material waste and minimizing post-production machining requirements. This not only saves time but also reduces overall production costs – an essential factor that benefits both manufacturers and farmers alike.

In agriculture specifically, valve casting finds application in various areas such as irrigation systems, pesticide delivery mechanisms, seed planting equipment, and more. By utilizing precision-crafted valves produced through this technique on farm machinery and equipment; efficiency is maximized while reducing downtime due to breakdowns or malfunctions.

The history of valve casting

Valve casting has a rich and fascinating history that dates back centuries. The origins of this technique can be traced back to ancient civilizations, where metalworking was first developed. In fact, the earliest known examples of valve casting can be found in ancient Egypt and Mesopotamia.

In these early civilizations, artisans would use primitive forms of casting to create tools and weapons. As metalworking techniques advanced over time, so did the process of valve casting. By the Middle Ages, skilled craftsmen were able to produce intricate valve designs using sand molds and other innovative methods.

The Industrial Revolution marked a turning point for valve casting, as new technologies allowed for mass production on a scale never seen before. Foundries sprung up across Europe and North America, fueled by the demand for valves in various industries including agriculture.

Today, modern advancements in technology have further revolutionized valve casting. Computer-aided design (CAD) software allows engineers to create complex designs with precision accuracy. Additionally, improvements in metallurgy have led to the development of stronger and more durable materials for valves.

The history of valve casting is characterized by innovation and continuous improvement. From its humble beginnings in ancient times to its current role in modern agriculture, this technique has played an integral part in shaping our world today. As we look ahead into the future, it’s exciting to think about how valve casting will continue to evolve and contribute to agricultural practices worldwide!

Find out the about the Dangwang Steel Casting Foundry in China

How valve casting is used in agriculture

Valve casting plays a crucial role in modern agriculture, providing durable and reliable components for various agricultural machinery and equipment. From irrigation systems to tractors, valve casting is used extensively in the agricultural industry.

One area where valve casting is widely utilized is in hydraulic systems. Hydraulic valves control the flow of fluids, such as water or fertilizer, within agricultural machinery. These valves need to be able to withstand high pressures and provide precise control over fluid flow. Valve casting ensures that these components are strong enough to handle the demands of field operations.

Another application of valve casting in agriculture is found in irrigation systems. Valves are used to regulate water flow, ensuring proper distribution across fields. The ability of valve castings to withstand corrosion and erosion makes them ideal for this purpose.

Furthermore, valves made through the casting process are also employed in seeders and planters. These machines rely on accurate seed placement at consistent depths for optimal crop growth. Valves help control the release of seeds into the soil with precision.

In addition to their functional benefits, valve castings offer cost-effective solutions for farmers by reducing maintenance needs and improving overall efficiency. By using high-quality materials and finishes during manufacturing processes like investment casting or sandcasting techniques depending on requirements enables extended lifespan even under harsh conditions.

While there may be challenges associated with sourcing specialized valve castings for specific farming applications or adapting existing designs to suit unique requirements, advancements in technology continue to address these obstacles.

The benefits of valve casting in agriculture

Valve casting plays a crucial role in modern agriculture, offering a range of benefits that enhance efficiency and productivity. One major benefit is the ability to create custom-designed valves that meet specific agricultural needs. With valve casting, farmers can have valves tailored to their unique requirements, ensuring optimal performance and functionality.

In addition, valve casting allows for the production of durable and long-lasting valves. Agricultural equipment is often subjected to harsh conditions such as extreme temperatures, chemicals, and heavy usage. Valves manufactured through casting processes are able to withstand these challenging environments without compromising their effectiveness.

Another advantage of valve casting in agriculture is cost-effectiveness. By utilizing this manufacturing method, farmers can produce valves at a lower cost compared to traditional machining or fabrication techniques. This affordability enables farmers to access high-quality valves without breaking the bank.

Furthermore, valve casting offers flexibility in terms of material selection. Farmers can choose from various materials like stainless steel or cast iron based on their specific application requirements. This versatility ensures that the valves used in agriculture are compatible with different types of fluids or substances they come into contact with during operations.

Moreover, valve casting provides faster turnaround times compared to other manufacturing methods. When time is critical for maintaining efficient farming operations, being able to quickly obtain replacement or custom-made valves becomes essential.

The benefits provided by valve casting make it an invaluable tool for modern agriculture. As technology continues to advance and demand for more efficient agricultural practices grows, we can expect further innovations in this field that will revolutionize how we use valves in farming operations

The challenges of valve casting in agriculture

Valve casting has undoubtedly revolutionized the agricultural industry, providing countless benefits and opportunities. However, like any technology, it also comes with its fair share of challenges.

One of the primary challenges faced in valve casting for agriculture is ensuring quality control throughout the manufacturing process. The valves used in agricultural machinery need to be durable and able to withstand harsh conditions in the field. Any defects or inconsistencies in the casting can result in malfunctions or breakdowns, leading to costly repairs and downtime for farmers.

Another challenge lies in the maintenance and repair of valve castings. As these components are often subject to intense heat, pressure, and wear over time, they may require regular inspection and replacement. This task can be time-consuming and labor-intensive for farmers who already have numerous responsibilities on their hands.

Furthermore, sourcing reliable suppliers of valve castings can prove challenging. Agricultural equipment manufacturers must find reputable foundries that produce high-quality castings consistently while adhering to strict delivery schedules. Failure to secure a trustworthy supplier could lead to delays in production or compromised product quality.

Additionally, there is an ongoing need for research and development within valve casting technologies specifically tailored for agriculture. As farming practices evolve with advancements such as precision agriculture and automation, there is a demand for innovative valves that can meet these changing needs efficiently.

Lastly,

environmental considerations play a crucial role when it comes to valve casting in agriculture.

The materials used in casting processes should be environmentally friendly,

and efforts must be made to reduce waste generation during manufacturing.

This sustainability aspect adds another layer of complexity but is essential

for maintaining a responsible approach towards our planet’s resources.

The future of valve casting in agriculture

Valve casting has long played a crucial role in various industries, and its significance in agriculture is no exception. As technology continues to advance at an unprecedented rate, the future of valve casting holds immense potential for transforming modern agricultural practices.

One area where valve casting is poised to make a significant impact is precision farming. With the ability to create intricate and customized valves, farmers can optimize water and nutrient distribution systems with unparalleled precision. This level of control not only enhances crop yields but also minimizes resource wastage.

Furthermore, as sustainability becomes increasingly important in agriculture, valve casting can contribute by enabling the development of more efficient irrigation systems. By incorporating smart valves that respond to real-time data on soil moisture levels and weather conditions, farmers can ensure optimal water usage while minimizing environmental impact.

In addition to precision farming and sustainable irrigation practices, valve casting also holds promise for enhancing automation in agriculture. With advancements in robotics and sensor technology, valves can be integrated into automated machinery that carries out tasks such as seed planting or fertilizer application with greater accuracy and efficiency.

Another exciting prospect lies in the integration of Internet of Things (IoT) technologies with valve casting systems. Imagine a network of interconnected sensors constantly monitoring soil conditions, pest infestations, or plant health – all linked directly to valves controlling various aspects of farm operations. Such smart networks could revolutionize decision-making processes by providing real-time insights for proactive management strategies.

As we look ahead to the future of agriculture, it’s clear that valve casting will continue evolving alongside technological advancements. From improved precision farming techniques to enhanced automation capabilities and IoT integration possibilities – there are endless opportunities for this ancient technique to shape the modern agricultural landscape.

Conclusion

In the ever-evolving world of agriculture, valve casting has proven to be a valuable tool. From its humble beginnings in foundries to its current role on farms and fields, this casting technique has revolutionized the way agricultural machinery operates.

Valve casting, with its ability to create complex shapes and intricate designs, has become an integral part of modern agriculture. It allows for precise control and regulation of fluid flow in machines used for irrigation systems, fertilization processes, and pesticide distribution. With valve casting technology, farmers can optimize their operations and achieve higher levels of efficiency.

The benefits of valve casting in agriculture are numerous. By using high-quality cast valves, farmers can reduce maintenance costs by ensuring equipment longevity. These valves are designed to withstand harsh environments and extreme temperatures commonly found in agricultural settings. Additionally, valve casting offers customization options tailored to specific needs or applications within the industry.

However, like any technology or process, there are challenges associated with valve casting in agriculture. Ensuring proper installation and maintenance is crucial for optimal performance. Any malfunctioning or leaking valves can lead to decreased productivity or potential crop damage if not addressed promptly.

Looking ahead into the future of valve casting in agriculture holds great promise. As advancements continue to be made in materials science and manufacturing techniques, we can expect even more durable yet lightweight castings that enhance overall machine performance while reducing energy consumption.

Furthermore, as precision farming becomes increasingly important for sustainable practices and resource management on an ever-growing global population scale it’s likely that new technologies will emerge alongside valve casting solutions – such as smart sensors integrated directly into cast components allowing real-time monitoring systems providing valuable data insights about plant health soil conditions water usage rates etc

In conclusion – Valve Casting plays a vital role at every stage of modern agricultural production from planting seeds through harvesting crops thus contributing significantly towards achieving sustainability goals profitability long-term ecological stability food security worldwide